Click Here for my article on the EWP installation from the Triumph Stag Club magazine..

August 2016:

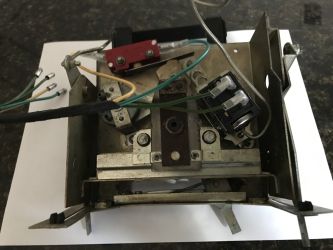

Rebuilt the heater A/C unit. I decided that I would loose the old 70s A/C components except for the evaporator in the heater

box. That way I can have a system that may actually work! I cleaned and tested the evaporator with a pressure check and vacuum

down, it seems fine. I removed the TXV and plugged the hoses, then filled it with nitrogen to prevent any corrosion. The

heater core was also tested and seems OK as well. I replaced most of the pop rivets with screws to make access easier next

time, (which I hope is never!) and tested and adjusted the fan motors. All flaps were checked and new seals inserted. The A/C

thermostat is shot, but I found a replacement that with a bit of modification should work. All of the vacuum components seem Ok

but its difficult to say at this point. I found out that the A/C Stag has a special 3 position fan switch that is not listed

anywhere, It took a long time but I found one in the end. I will purchase a Sanden compressor, a condensor that will fit the

front of the radiator and dryer, modern pressure switches and a new TXV valve. The hoses will be made up once I get the stuff

mounted. However in the end I decided not to re commision the A/C, I always have the hood down and do not have a hard top.

Oct 2017:

Got the Mark2 pulley and how wrong I was. The smaller fan and clutch that I assumed was a Mk1 was in fact a TR7 item, the

proper Stag fan and clutch was a MK1 and is in good working condition. The Mk1 pulley has a cut end that fits nicely into the

clutch, the mark2 pulley is the same but sits about 1/2 inch further forward. The pulley I got with the MK2 is neither one or

the other. Problem is that the MK1 pulley has a lot of rust and I'm worried that it will wear the fan belt through so I have

given the inbetween pulley to the machine shop to turn it down into another Mk1 pulley and I'll use that one.

All this because I have decided to leave the stock fan in place initially, word is that it helps circulate air around the

engine compartment and helps keep the engine bay temps down when an electric fan is used. I will make a decision on the

electric fan and its size later.

Picture below shows the MK1 on the right (a mk2 looks exactly like that but is as tall as the black one ) and the black

unknown "kinda mk2" on the left may actually be the one for the metal A/C type fan?.

*Click on images for bigger version*

Jan 2020:

I tested all of the vacuum parts for the heater system, surprise was that they all seem to work so The Heater was installed

and all of the vacuum and mechanical components were connected up. I hope it works!. Also found the A/C wires taped into the

loom, so released them and reterminated any that needed it. The generic A/C thermostat worked out fine, it was just a matter

of changing the cover over from the old one, then I installed the new TXV valve. I did a final pressure test of the heater matrix and it seems fine, no leaks.

*Click on images for bigger version*

August 2020:

I have decided to go with just the Electric fan If I use the mechanical as well it would need a shroud which I cannot find,

plus that shroud interferes with a pusher fan. I feel that The TR6 spoiler I have fitted will solve any problems at speed,

and the Electric fan will push a lot more air at idle plus it can run after engine switch off. The only downside would be

the possible loss of airflow in the engine bay. Meanwhile I checked out my Radiator, Flushed it and pressurised it up to 30psi

and there was a slight leak from one of the header tanks. I was succesfull in soldering that up. The planned header tank

needed an extra pipes o to be soldered in and that was succesful. Once I get the Engine in and the EWP planned out I can

decide where that would go. However after installing it, the radiator leaked like a sieve I guess the stresses were too

much for the old solder. A Supergill core was obtained from Tony Hart and it was installed at one of the few radiator shops

left in the area.

*Click on images for bigger version*

August 2020:

Firstly the 16" pusher fan was installed, 3000 CFM was about as high a capacity as they come. I had to open up the radiator

side braces a little but it fits well on the generic brackets I had obtained. Now the Davies Craig pump and header tank needed

to be plumbed in. I had decided to mount the EWP low left as I did not want to move the alternator with a view to A/C in the

future, also as I was without a mechanical fan it was a viable position. NAPA Online has the great ability to search through

thousands of water hoses, seeing the shape and sizes so 3 likely candidates were selected. I wanted the hose from the bottom

of the radiator to drop a little to clear the crank, and run directly into the pump. Then from the pump it runs up to the

inlet of the engine, the former pump cover. 2 worked, one was returned. There was also a "T" in the lower hose for the heater

return. The sensor was Tee'd in to the top hose. I had included the pump and sensor wires in the loom when I redid them so

the install is neat and tidy. Even the latest version Controller is a bit unwealdy for mounting on the dash so it was

installed in the glovebox, a common method apparently, once you stop stressing over it its really does not need to be in

plain view. On the other hand I got a 16mm Led dash light for the controllers overtemperature warning and I placed it

smack in the middle of the dash in place of the now deleted seatbelt warning light, I don't want to miss that if it ever

lights! The heater is working well.. to well, its on all the time. By disconnecting the vacuum pipe from the heater valve I

established that the vacuum control is not fully functional, for now I have left it disconnected, a job for the winter, I can

always connect it up again when the wether turns colder. In any case after driving the car around in the heat I am wondering

if I really want to go ahead with the A/C system. I will never use a hard top and will only use the softop when its actually

raining so cannot really justify the bother and expense. So I will consider what to do over the winter, weather the original

vacuum system can be made to work or some other way, maybe a servo or a bowden cable for the heat. The flaps are working fine

on vacuum.

*Click on images for bigger version*

August 2020:

Once that was sorted I installed the VW ball type header tank which seemed to me to fit well and has a convenient way of

checking the level.. You can see it!

*Click on images for bigger version*

September/October 2020:

Now I'm Driving the car I was at first experiencing "Stag Stress" over the coolant temperatures. However all is well. Many

early drives were in high heat, up to 98 degrees and it has performed well. I had a mild initial concern about when and how

the fan came on but once you logically think about whats happenning, e.g the fan coming on after a fast run when the engine

was heated but the car is now running slowly, is acting normaly given its without a mechanical fan.

Bottom line is that its never overheated and is performing well. The running engine bay temps are fine and with the fan and

pump running on after ignition off its well under control. The OEM temperature guage was wildly overreading due to the

currently available senders being wrong, so to satisfy my inner woryywort I found a resistor to bring it down to 1/2 scale

at running temperature. I have set the Davis Craig controller to 90 degrees, this is about where a 88 degree stat would sit

at they only start opening at 88. The only issue I see is when its colder, its taking a long time to get up to any kind of

temperature and sometimes even drops when you are driving. The EWP does not have a bypass or thermostat, but it can be used

with them as long as the bypass is fed back to the input of the pump. However as I have a Mk1 inlet manifold that does not

close the bypass and I am concerned about that for summer running I am going to just try the Davies Craig recommendation of

fitting a thermostat but drilling a hole in it to give some bypass. I have selected a High flow 82 degree stat as I want it

to be fully open in the summer. Another winter job, then see how it does in the summer.

December 2020:

As suspected the engine is not getting anywhere near the set temperature now that its cold, so The thermostat was installed

with 2x3mm holes as suggested by Davies Craig. I ended up setting the controller to 85 degrees to get it nearer the 82 degree

thermostat that was installed and its working out fine, the temperatures get up fairly quickly with no issues and stays there.

Once the summer came I left it in but raised the setpoint to 90 degrees and its performing well, no issues at all when driven

hard on 97 degree days, no more Stag stress here! The Heater works great, nice and toasty, but I just cannot get the vacuum

heat controls to operate properly, new components are unobtainable and getting to them under the center console is a PITA so

for now I just connect the water valve up to vacuum in the winter for full heat, disconnect in the summer for no heat.