SU Needle polishing

First a little theory.

The SU carb uses engine depression to raise a piston in the Dashpot. Attached to the piston is a shaped needle and the piston itself acts like a valve for the air. The higher the piston the more air is allowed in and as the needle is pointy the more fuel gets in. Its a big balancing act between the fuel and air and the shape of the needle determines the ratio. It is important to remember here that the

amount of depression does not depend on rpm, but on the load of the engine, i.e how much air it is gulping.

In a turbo HIF this is slightly modified because now everything is under pressure from the turbo. The neat way they got around that was to install a small restrictor plate in the plenum, this ensures that the pressure before the restrictor is slightly higher than inside the carb throat. That slightly higher pressure is fed through drillings firstly into the float chamber to "pressurise" the fuel.

and secondly to just below the piston to raise it.

Note** the fuel pump and regulator DO NOT give the fuel inside the carb any pressure, the regulator is just there to make the fuel pressure 4 psi or so above the pressure inside the float chamber so that fuel can DRIP in to replenish what is used, this way the little valve is not overwhelmed by 16psi of pressure.

The Dashpot spring determines how high the piston rides for a given depression. You should use the lightest spring that allows the piston to raise fully to the top at WOT to ensure quick response to the throttle. If it gets to the top before WOT or never gets there then you have the wrong spring. I am investigating other ways of seeing this in the other pages of the tech tips. The standard 8oz should be fine, maybe a 12oz just adjust the profile of the needle to suit it. Some people use double springs (16oz) I tried this, It was almost impossible to stop them binding and the engine was less responsive (a slug!), therefore with 8-12psi I would not even think of using a double spring.

Dashpot oil is used to enrichen the mixture in a snap open throttle situation, the oil resists the piston lift and the resulting lower than normal piston height "chokes" the engine and causes more fuel to be sucked in until the piston reaches its normal height, then the balance is restored. Start with a light oil then keep trying heavier oil till it snaps open without hesitation, Standard SU dashpot oil is 20wt. Another thing to keep in mind is that the oil does affect the WOT mixture, with heavier oils the piston is almost always lagging a bit and this makes the mixture richer until it catches up, and it probably never will whilst you are changing gears.

And finally on a turbo carb there is a part throttle lean pipe on the carb, I found that removing and plugging it enrichens the mixture quite a bit but with it installed the cruise mixture seemed more stable, In the end though I found that the mid throttle fuelling was better with the pipe disconnected and plugged.

There is a great book called "how to build and power tune SU carberettors" by Des Hammill it covers the subject wonderfully ...except for the turbo differences..

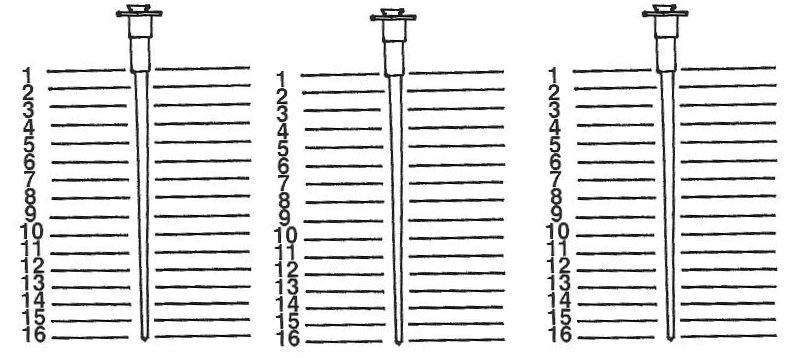

Select a starting needle that is basically lean, a BDD would be a you good start for most turbo Mini's but if you choose to plug the part throttle lean pipe you may need something leaner. To do this properly you really need to be able to see the fuelling and the piston position so a wideband O2 sensor is best and to see the piston height I made a lift indicator for details check out my other tip . However for cruise the stick shown below is fine but as soon as you drive the car and the turbo starts blowing it wont work-- or be drivable as the chamber needs to be sealed. Then print this image up, make it the same size as a real needle (on my printer image height set to 2.55")

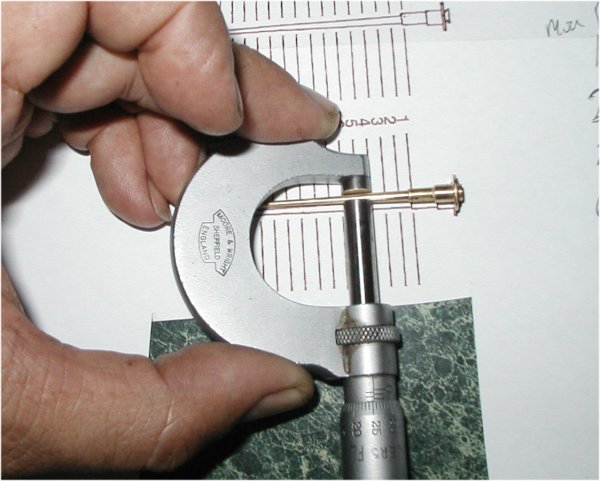

Measure your needle using the 16 "stations" as a guide. Just hold the micrometer over the paper with the front edge of the anvil lined up with a station, and close it down, until the needle when pushed in lines up with the image. Thats your reading at that station. In this case 2.25mm at station 4.

Next using another of the images make a stick with the same measuring points on it. (even better, check out my other tip on making a sealed turbo piston lift indicator)

Before you re-install the dashpot, take a look at how far down the jet is from the bridge (hopefully you have previously installed the needle and established the idle setting) install the needle and dashpot, insert the stick and adjust it to leave about the same amount showing above the dashpot like this..

Now start the engine and warm it up, you will see that the stick moves up and down according to the lift of the piston, the lines give you a good idea which "station" is currently in use, here we are at about station 6. Dont forget that without the damper the engine will stutter if you snap the throttle so move it slowly.

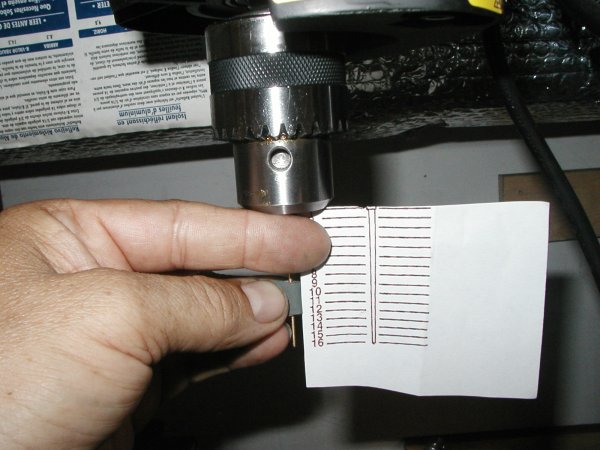

Now you can start checking. slowly raise the rpm and hold and note what happens at 1500, 2000, 2500 etc up to 4000 (when an unsealed turbo carb starts blowing and the piston shoots up), also note what station is showing. If you have a wideband great its easy just look for 14.7 if you have a narrow band still Ok just see if its lean or rich. If its lean, great you can polish, if its rich then you probably want to get a leaner needle to start with. Once you have an idea of what stations need polishing down you can start. Take the needle, lightly mount it in a drillpress (I held onto the needle as I started the drill, and used my fingers to centre it) and use the paper to give yourself an idea where to polish use some 600 grit wet-n-dry (note-- here I am on a much higher station than you would normally be for this part of the proceedings)

Give it a squeeze for around 5 seconds, I found this gave about a 0.01mm correction, enough for a small adjustment, but you have to experiment here. Dont try to do it all at once, keep re-installing and testing it. I also found that marking the stations above and below with a marker pen helped me keep to the right area.

Next you need to work on the next stations. I found it best to use a light oil in the dashpot at this point so that the readings were more accurate.

Without a sealed lift indicator you are going to have to guess. In my case light throttle was stations 6-7. then go for a 3/4 throttle acceleration station 9-10, and finally full throttle which should be around station 12 unless you have the wrong spring fitted.

With a sealed indicator its a case of holding the throttle and accellerating just enough to keep the indicator at a station and once it stable take a quick look at the O2 sensor and you will see if its lean or rich, polish accordingly. I found that 0.03mm was giving me about a change of 1 on the AFR.

I also had trouble seeing the numbers on the lift indicator so I used a small tiewrap around it to show what station I was looking for and just slid it up and down as needed.

You will probably screw up the first needle! but every time you try this you learn what stations do what and the next one is always better, stick with it.

Polishing needles takes a big learning curve but here are some of the things I found with my setup.

I needed quite a step from station 5 to 6 to prevent leanout when pressing the throttle from cruise, the position of this step depends on a lot of factors but it may be that because I am using a small light turbo that spins up easily it was moved up the needle. The dashpot oil you use has a big effect on the WOT AFR. if its thicker, the piston never really gets to its final position in the short time you can hold the throttle open. Because of this you may see some leanoff in top gear when it finally catches up. When I had the leanoff pipe connected I also saw problems with a leanoff when I held the throttle open just enough to give full boost, in this case the piston does catch up and it highlights the lean needle you really have, any attempt to fix this caused overrich mixtures at WOT.

In the end I went all the way down to a 10wt oil to get the balance between this and WOT to be reasonable but not perfect. This is why I would suggest blocking the leanoff pipe..

Back to Tech Tips page